Iron Mountain Subsurface Characterization

Project Description

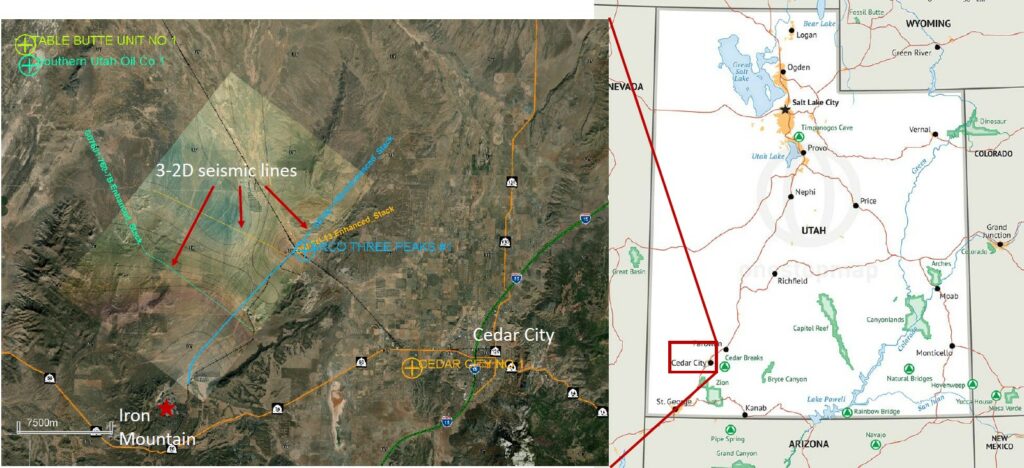

The University of Utah (UU) is working to develop a CCS project at the Iron Mountain iron mine, located near Cedar city, Utah. The focused project seeks to enable the mine to realize CCS associated with direct reduced iron (DRI) processing, producing ‘green’ steel. The project team includes site operator Utah Iron LLC as well as the Utah Geological Survey, Kansas Geologic Survey, Oklahoma University, Oklahoma Geologic Survey, Montana State University, NMT, Los Alamos National Laboratory, CarbonSolutions LLC, and CandaceCadyConsultingLLC.

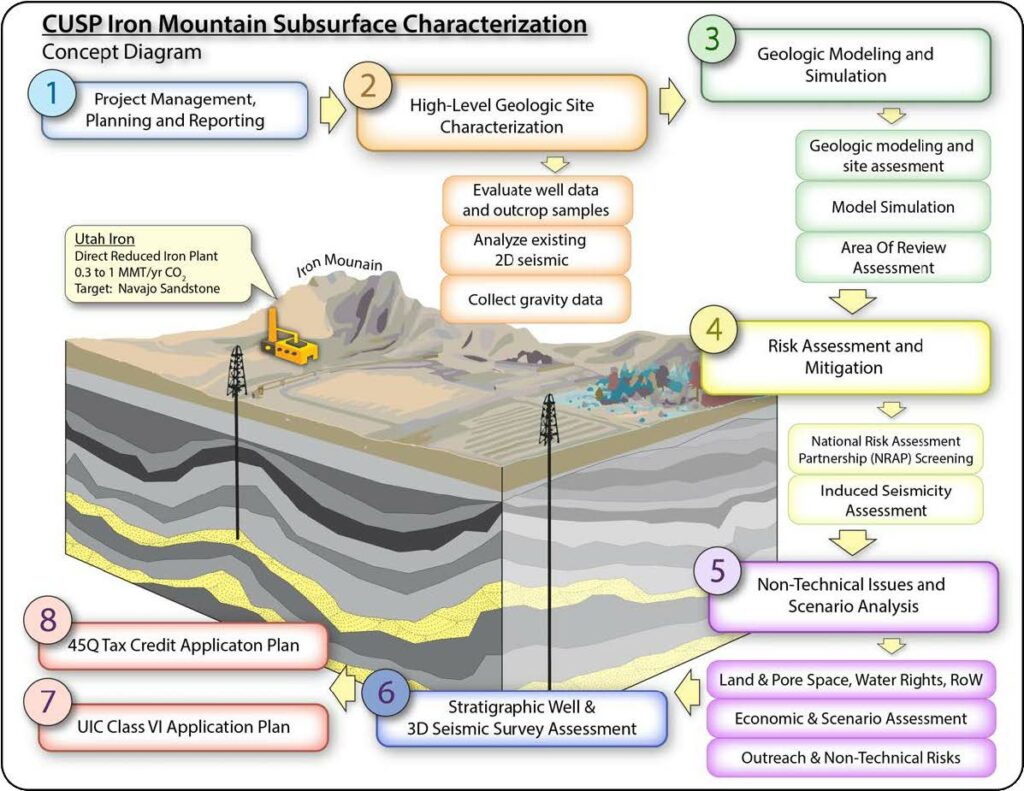

The main goal of the project is to evaluate the feasibility of storing 0.3 to 1 MMTCO2 generated from the direct reduced iron (DRI) process, and the project would be the first of its kind. The DRI process refers to the solid-state processes of reducing iron oxides to metallic iron at temperatures below the melting point of iron. During this process, CO2 and H2O are produced by CH4 catalysis, and heated before entering the reactor (Fig. 3). Iron reduction reactions occur producing CO2 and water. The CO2 can then be stripped, out, compressed, and stored while iron is cooled and sent for further processing into steel.

If successful, the CCS project will be the first commercial-scale CCS operation in Utah and serve for other potential basin and range storage sites. But most of all, it will prove the viability of using CCS to make green steel and new innovations may also result in H2 production.

CUSP Team

Project Lead: Nathan Moodie (UU) Industry Partner: Utah Iron LLCPrimary Goal

CCUS Feasibility Study for Direct Reduced Iron ProjectImpact on Carbon Storage

First of its kind commercial-scale iron ore processing + CCSProject Duration

36 monthsAnticipated Time to Storage

5-8 yearsAnticipated Volume/Year

0.5 to 1.0 Mt/year over 30 years

Project Objective

The success of the project depends explicitly on the target storage formation and its specific geologic setting, and the feasibility study follows a typical workflow.

The process to study the project feasibility is: (1) rigorous site characterization and analysis of storage capacity, risks and economic options for CCUS at Iron Mountain, (2) develop a monitoring, reporting, and verification (MRV) plan,

(3) Comprehensive plan for 3D seismic survey and stratigraphic well, (4) assemble UIC Class VI and 45Q tax credit applications.